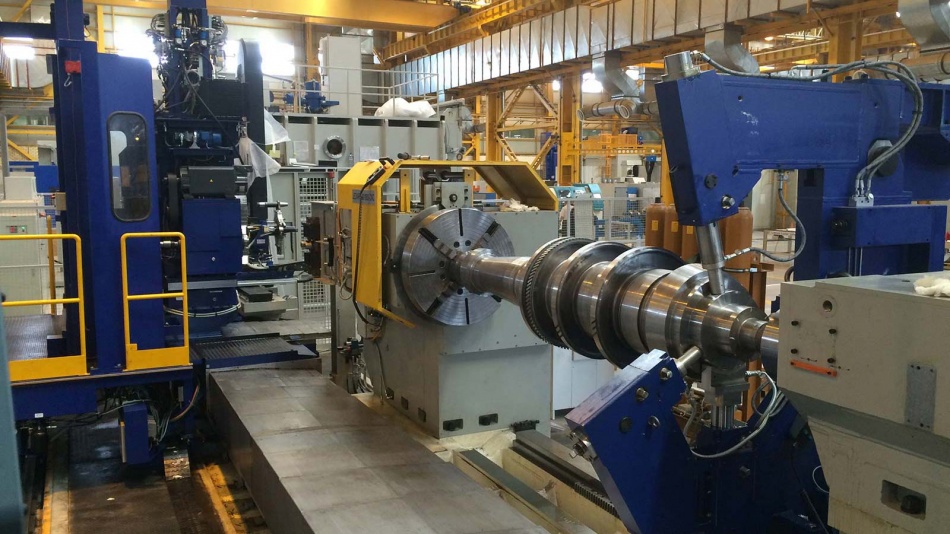

The Leonard machines are a complete and modular range of Horizontal Lathes for the machining on medium to large work pieces with highest performances in terms of rigidity for rough operations and precision for finishing operations.

The main feature of these models is the hydrostatic support.

The advantages of this technology are: movements without friction and elimination of "stick-slip" phenomena, long life of the guides due to the absence of wear, precision of positioning of the axes thanks to the "soft" movements, absorption effect of vibrations caused by cutting forces with consequent safer and more rigid movements for the longitudinal and transversal guides of the wagons.

All the Leonard Lathes are designed with 4 ways, therefore the carriage can pass freely either at side of the tailstock and steady rests. Depending on the model they can have a single bed or double bed.

The headstock unit is designed with three speed range and it can be equipped with high precision indexing “C” axis. The spindle can be supported by conventional roller bearings or alternatively by Hydrostatic bearings in case of high precision machining needs.

On the Hydrostatic carriages different turning units can be supplied according to the requests: Blades, Square turret, Disc turret 12 positions eventually with motorized tools. The double carriage option is available.

In addition to the turning units on the carriages it is possible to mount boring equipment, milling units with or without vertical and grinding "Y" axis.

These different units can be applied on a column equipped with rotation (axis "B") or positioned on different pallets to be mounted on the carriage manually or automatically.

The Leonard lathe can be supplied with different type of Steady rests according to the work piece and the required machining.On demand different accessories are available like the work piece probe, the tool probe and the Automatic tool changer.

Safop has developed some special system for the measuring of high sophisticated work pieces like the turbine rotors. The Run Out Measurement System and Blade Measurement System are used with success by the main producers of this type of work pieces.